Fabrication methods

Step by step towards success

Every accelerator device is different. Defining the optimal fabrication sequence is critical to meet the functional requirements.

Material sourcing

Alloys, thermal treatments, processing methods, shapes, etc. every detail is looked up to meet the specification. We collaborate with the CERN material store and with industrial partners to find the optimal raw material for every component.

Fabrication drawings

Complex components require specific drawings for every fabrication step, for example to ensure the right fit before brazing or electron-beam welding joints. Our designers make sure to meet both the fabrication technical requirements and the functional requirements.

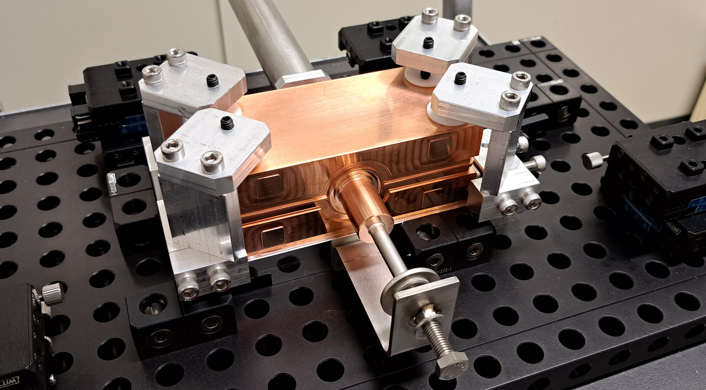

Tooling design

The fabrication of some parts requires custom made tools. Tools are optimally dimensioned to meet their function while being easy to manufacture.

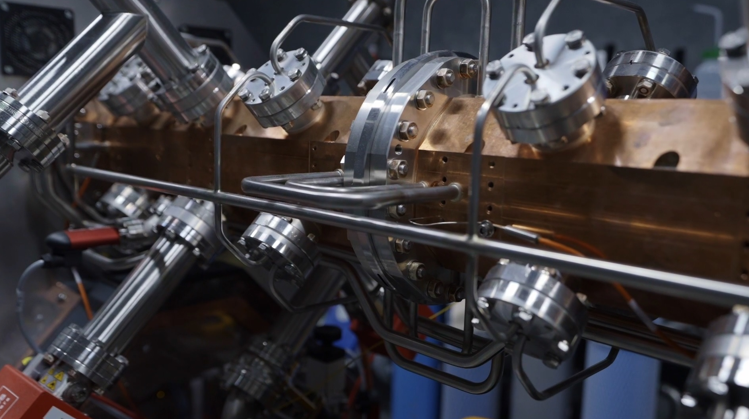

Multi-technology fabrication projects

Expertise in devices requiring a combination of state-of-the-art fabrication technologies. We connect the different workshops and teams for a successful manufacturing: machining, welding, brazing, intermediate surface or thermal treatments, forming, dimensional controls, assembly, non-destructive testing (NDT), etc. The functional drawing folder is the starting point to prepare the fabrication sequence.

Prototyping

The number of components to produce has an influence in the optimal fabrication process. Large series require prototype units to validate the fabrication sequence. Our expertise allows to envision the series production and reproduce the fabrication conditions.

FIND OUT MORE

Keen to learn more about our activities?

Find out what the Fabrication, Method and Subcontracting unit can do for you.